Client Snapshot

The Client is a manufacturer of packaging solutions, machinery,

products, and materials for the food processing industry. Their

products deliver value through technology, increased efficiency,

and long-term reliability. With distribution centers in the U.S. and

abroad, the Client works with food processors across the globe.

The Challenge

The Client’s freight consists most often of large machinery,

equipment, and machine parts. The freight is large, heavy, and

often time-sensitive. When a customer’s machine needs repair, a

halt in production to repair it can cost the customer thousands of

dollars every hour, creating a critical need for high-quality

expedited shipping. With only a few distribution centers spread out

across the U.S., same day delivery to all customer locations requires

the use of both air and ground expedited services. With an annual

freight spend nearing $750,000, the Client ships on average 1,400

Less than Truckload (LTL), 130 Full Truckload (FTL), and 500

Expedited shipments each year. The Client had developed a strong

relationship with a single carrier, who was able to provide

consistent quality of service, however freight costs and accessorial

charges were high. Additionally, they lacked visibility into shipment

trends and spend across locations. With a growing business, the

Client needed a partner who could provide both sustained cost

savings and visibility into their supply chain.

The Solution

eShipping’s Supply Chain Analysts conducted an in-depth logistics

study, reviewing factors such as freight characteristics, accessorials,

distance, direction, rates, and more. The study identified

opportunities for optimization and rate savings, and a solution was

implemented that focused first on the Client’s LTL freight. A preferred carrier mix was developed that leveraged the Client’s

existing carrier relationship, along with strong regional and national

carriers to maintain service levels and quality, while reducing overall

transportation cost. As part of the carrier optimization strategy,

eShipping procured a reduced rate with the existing carrier.

eShipManager® TMS was implemented across locations, allowing

for real-time rate optimization, accessorial management, and

visibility into shipment data. After implementation, performance

data was provided to the Client on a regular basis and the solution

was expanded to include full truckload and expedited freight.

The Results

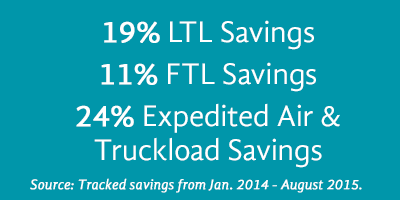

As a result, the Client has realized a 19% reduction in LTL freight

spend, an 11% savings on FTL spend, and an average 24% cost

savings on expedited air and truckload shipments. In addition to

cost savings, the Client has benefited from the ingenuity and

dedication of eShipping’s operations team. An example of this is

when an expedited air shipment was delayed by inclement weather

because all flights in and around the destination city had been

cancelled. eShipping contacted carriers until one was found willing

to pick up the time critical shipment from the airport location in the

snowstorm and deliver on schedule. The ability to expedite these

types of shipments at a reduced rate without sacrificing the quality

of service has helped the Client support their customers efficiently

while keeping costs down. The Client has also gained visibility

across locations and is able to utilize business intelligence to more

accurately forecast freight spend and ongoing needs.

Download a PDF of this Client Success Story

Download a PDF of this Client Success Story